[email protected]

[email protected]

+86 181-5747-1135

China Germany Standard Automotive Wire Manufacturers wholesale Germany Standard Automotive Wire Factory

+86 181-5747-1135

China Germany Standard Automotive Wire Manufacturers wholesale Germany Standard Automotive Wire Factory

Established in 1998, Zhejiang Jiahui Wire And Cable Co.,Ltd is a professional China Germany Standard Automotive Wire Manufacturers. To provide customers with best service and guarantee products quality, we are using advanced ERP, MES and SAP for all incoming and outgoing data management. As a professional wholesale Germany Standard Automotive Wire Factory, Our factory devotes to producing Germany Standard Automotive Wire, automotive wire, power cable and high temperature wire etc. We also get certification of UL,CE,VDE,TUV,SAA,CCC,GS etc. and all our products comply with ROHS and REACH environment standard.

More than 22 years of industry experience

Covers an area of 30,000 square meters

More than 200+ employees

Our annual production capacity is over 500,000km/year.

High Performance Production Machine,7S Site Management , Precise Laboratory Equipment

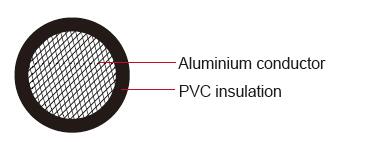

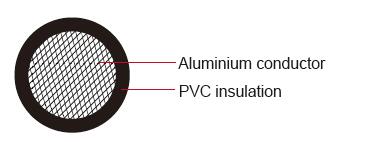

The operating temperature range of this aluminum conductor PVC coated automotive wire is from -40°C to +125°C, covering a wide range of temperatures f...

UL3122 Silicone Fiberglass Braiding Wire, as a wire product designed for high-performance applications, has a core material for its insulation layer m...

The application of XLPE insulation in automotive wires has shown significant advantages in many aspects compared with other insulation materials. Thes...

Teflon cables are mainly suitable for a variety of applications that require high temperature resistance, corrosion resistance, and good insulation pe...

VDE H05SJ-K Fiberglass Silicone Wire, as a high-performance wire material, play an important role in the internal wiring of many fields and types of p...

The "PI film + white silk" type design plays a vital role in the manufacture of Silk Cover Stranded Enameled Magnet motor winding wire high frequency ...

A Strong Connection: The Influence of Germany’s Automotive Wire Standards on Vehicle Reliability

In the realm of modern transportation, the reliability of vehicles rests upon a foundation that often remains concealed – the meticulous standards governing automotive wiring. Germany, a paragon of precision engineering and quality, has wielded a profound influence in this domain. The impact of Germany’s automotive wire standards on vehicle reliability is a narrative of intricate craftsmanship, rigorous testing, and unwavering commitment to excellence.

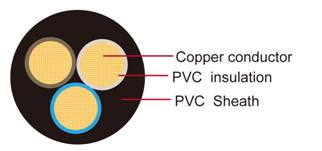

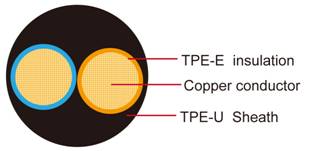

At the core of Germany’s automotive wire standards lies an uncompromising devotion to impeccable craftsmanship and the use of top-tier materials. These standards dictate the employment of resilient, heat-resistant, and corrosion-proof materials for wiring and harnesses. Such discerning material selection ensures that the wiring can endure the demanding conditions within vehicles, from ceaseless vibrations to fluctuating temperatures. By setting an exceptional standard for materials, Germany’s approach paves the way for heightened reliability, culminating in fewer failures linked to wiring, which in turn solidifies the dependability of vehicles.

In the intricate landscape of modern vehicles, seamless electrical connectivity is paramount. Germany’s automotive wire standards champion this cause by stipulating precise manufacturing tolerances and secure connector designs. These exacting parameters mitigate the risk of subpar electrical connections that can set off a chain reaction of malfunctions. A sturdy electrical foundation, bolstered by these standards, yields consistent performance and minimizes the likelihood of unexpected electrical anomalies, thereby amplifying the overall reliability of vehicles.

Vehicles navigate an array of environmental extremes, from scorching heat to freezing cold. Germany’s automotive wire standards stand as a barrier against these adversities, incorporating insulation materials and protective coatings that defy nature’s onslaught. By imparting the ability to weather these challenges, these standards erect a bastion against potential reliability pitfalls, ensuring that a vehicle’s electrical system remains steadfast, irrespective of the elements.

A tapestry of standardized wiring practices underscores the reduction of potential weak points within a vehicle’s electrical framework. Meticulous designs and meticulous routing shield wires from physical damage, abrasion, and interference with other components. This streamlined approach curtails the probability of unforeseen electrical hiccups, charting a course towards enhanced vehicle reliability.

Germany automotive wire standards are not static; they mirror the dynamism of the industry. These standards adapt seamlessly to assimilate the latest technological marvels and insights. This inherent adaptability guarantees that vehicles engineered in alignment with these standards embody cutting-edge wiring technologies and design refinements. The pursuit of excellence, integral to these standards, becomes a conduit through which vehicle reliability and performance ascend continuously.